Cryogenic Insulation

Cryogenic insulation is a specialized service essential for maintaining extremely low temperatures in various industrial applications. Al Mukhtar Group provides expert insulation and jacketing solutions specifically designed for cryogenic environments, such as LPG/LNG tanks and pipelines, ammonia lines, metering skids, and process skids. Our insulation techniques ensure that the integrity of these systems is maintained, preventing heat ingress, reducing energy loss, and protecting against temperature fluctuations. With our extensive experience and commitment to quality, we ensure that your cryogenic systems operate efficiently and safely, even under the most demanding conditions.

Hot Insulation

Al Mukhtar Group offers comprehensive hot insulation services using premium materials such as Rock Wool, Ceramic, Foam Glass/Cellular Glass, and Calcium Silicate. Our insulation and jacketing solutions are designed for a wide range of industrial applications, including Oil & Gas fields, FPSOs (Floating Production Storage and Offloading units), Modules/Skids, Refineries, Power Plants, Fertilizer and Cement Plants, Petrochemical Plants, and various other industries. Our expertly engineered insulation systems help in managing high temperatures, improving energy efficiency, and enhancing safety across diverse industrial operations.

Cold Insulation

Al Mukhtar Group provides specialized cold insulation services using advanced materials such as Polyurethane (PU), Polyisocyanurate (PIR), Elastomeric/Rubber, and Fiberglass. Our insulation and jacketing solutions cater to a variety of sectors, including Buildings, Commercial facilities, Industrial operations, and the Oil & Gas industry. These cold insulation systems are designed to maintain low temperatures, reduce energy loss, prevent condensation, and ensure operational efficiency across multiple applications. We ensure durable, high-quality insulation that meets the unique demands of each sector, delivering reliable performance and cost savings.

Acoustic Insulation

Al Mukhtar Group offers specialized acoustic (soundproof) insulation services designed to reduce noise and vibration in various commercial, oil & gas, and industrial environments. Our insulation systems are ideal for engine rooms, generator rooms, pipelines, and other noise-sensitive areas. By using advanced materials and techniques, we ensure effective soundproofing that meets regulatory standards and enhances operational comfort. Whether it’s reducing machinery noise or controlling acoustic levels in critical areas, our solutions deliver superior sound management for a wide range of applications.

Personnel Protection Works

Al Mukhtar Group provides specialized personnel protection solutions using Wire Mesh Guard, Perforated Sheets, and Rock Wool insulation. These systems are designed to safeguard workers from extreme temperatures and hazardous conditions in Oil & Gas fields and industrial sectors. Our protective insulation solutions ensure that high-temperature equipment and pipelines are securely covered, minimizing the risk of burns or injuries. By integrating durable materials and industry-standard safety measures, we offer comprehensive protection for personnel working in challenging environments, while also maintaining operational efficiency.

Refractory

Al Mukhtar Group offers expert refractory lining services for the industrial sector, specializing in applications such as boilers, furnaces, autoclaves, and other high-temperature equipment. Our refractory linings are designed to withstand extreme heat, corrosion, and wear, ensuring the longevity and efficiency of your industrial systems. By using high-quality refractory materials and precise installation techniques, we help enhance thermal performance, reduce energy consumption, and protect equipment from thermal degradation, ensuring reliable and safe operation in demanding industrial environments.

Flexible Jacket Insulation

Al Mukhtar Group provides customized flexible thermal jackets for vessels, valves, instruments, steam turbines, and gas turbines. These removable and reusable jackets are designed to provide superior thermal insulation, reduce energy loss, and improve operational efficiency in industrial applications. Our thermal jackets are tailored to fit a wide range of equipment, ensuring easy installation and maintenance while offering excellent protection from heat and temperature fluctuations. Ideal for high-temperature environments, these jackets help improve safety, conserve energy, and extend the lifespan of critical machinery.

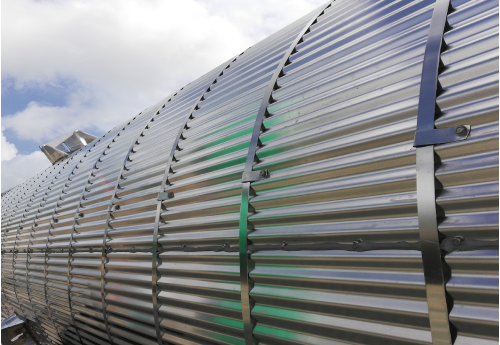

Jacketing(Cladding) Works

Al Mukhtar Group offers all types of jacketing services using high-quality materials such as Aluminum, SS316, SS304, Aluminized Steel, AluZinc, and Galvanized Iron (GI) over insulation systems. These jacketing solutions are designed for a wide range of applications, including the Oil & Gas field, Power Plants, Cement Plants, Industrial applications, Metering and Process Skids, Commercial Buildings, HVAC systems, and District Cooling Plants. Our durable jacketing systems protect insulation from external factors such as weather, moisture, and mechanical damage, ensuring long-lasting performance, enhanced safety, and reduced maintenance across various industries.

Fire Proofing & Fire stop works

Al Mukhtar Group specializes in passive fireproofing for structural steel, vessels, equipment, and fire sealing of MEP (Mechanical, Electrical, and Plumbing) penetrations in commercial and industrial buildings. Our fireproofing systems are designed to protect critical structures and equipment from the damaging effects of fire, ensuring compliance with safety standards and extending the fire resistance of materials. By applying advanced fireproofing coatings and sealants, we help contain fires, prevent structural collapse, and protect vital equipment, providing essential safety and protection for both commercial and industrial environments.